Categories

New products

-

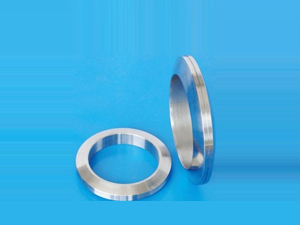

Lens Ring Joint Gasket

Kaxite specialized in Supplying & Manufacturing Lens Ring Joint Gasket, timely delivery short 5-10 Days, Custom Lens Ring Joint Gasket, Better choice selecting Kaxite sealing.

-

Double Jacket Gasket

Kaxite specialized in Supplying & Manufacturing Double Jacket Gasket, timely delivery short 5-10 Days, Custom Double Jacket Gasket, Better choice selecting Kaxite sealing.

-

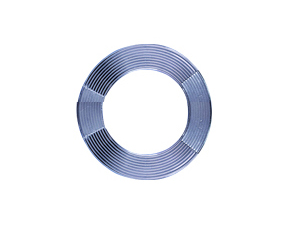

Corrugated Gaskets

Kaxite specialized in Supplying & Manufacturing Corrugated Gaskets, timely delivery short 5-10 Days, Custom Corrugated Gaskets, Better choice selecting Kaxite sealing.

-

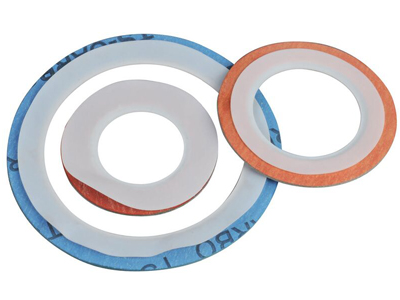

PTFE Envelope Gasket

Kaxite specialized in Supplying & Manufacturing PTFE Envelope Gasket, timely delivery short 5-10 Days, Custom PTFE Envelope Gasket, Better choice selecting Kaxite sealing.

-

Rubber Sheet

Kaxite specialized in Supplying & Manufacturing Rubber Sheet, timely delivery short 5-10 Days, Custom Rubber Sheet, Better choice selecting Kaxite sealing.

Oil-Resistance Asbestos Rubber Sheets KNY250

Made of good long asbestos Fibre, oil-resistance synthetic rubber, heat-resisting packing material compound heating and compression molding it and used as sealing material in the joints of oil pipeline and sealing gasket used on automobiles motorcvcles, agricultural machines, engineering machinery engines

|

|

|

Material: Made of good long asbestos Fibre, oil-resistance synthetic rubber, heat-resisting packing material compound heating and compression molding it and used as sealing material in the joints of oil pipeline and sealing gasket used on automobiles motorcvcles, agricultural machines, engineering machinery engines Uses: Mainly used as the sealing gasket material for the equipment in kerosene, petrochemical, alkali, solvent, fuel oil, petroleum-based lubricating oil and other mediums. Working pressure: 2.5Mpa , Max working temperature: 250 oC Sizes: 1500 x 1360 x (0.5 - 6.0)mm, 1270 x 1270 x (0.5 - 6.0)mm,1500 x 1500 x (0.5 - 6.0)mm Packing: in wooden pallet of about 1000 kgs, 2000kgs net each. |

|

Oil-resisting Asbestos Rubber Sheets Physical Property GB/T539-2008 |

|||||||

|

Item

|

KNY510

|

KNY400

|

KNY300

|

KNY250

|

KNY150

|

KNY300

|

|

|

Tensile strength MPa

|

18.0

|

15.0

|

12.7

|

11.0

|

9.0

|

12.7

|

|

|

Compressibility %

|

7-17

|

||||||

|

Rebound Rate%

|

50

|

45

|

35

|

50

|

|||

|

Creep relaxation rate%

|

45

|

-

|

45

|

||||

|

Density g/cm3

|

1.6 - 2.0

|

||||||

|

With the temperature

of 149 dipped in IRM903 aviation luricatint oil for 5h |

Horizontal Tensile strength MPa

|

15.0

|

12.0

|

9.0

|

7.0

|

5.0

|

9.0

|

|

weight-increasing%

|

30

|

||||||

|

Surface

change |

-

|

No bubble

|

|||||

|

With the temperature

21-30 dipped in ASTM B fuel Oil aviation luricatint oil for 5h |

weight-increasing%

|

0-20

|

-

|

0-20

|

|||

|

With the homoeothermy,

oil seal Performance |

Pressure (MPA)

|

18

|

16

|

15

|

10

|

8

|

15

|

|

Seal require

|

Keep 30 minutes,no leak

|

||||||

|

Nitrogen leakage rate

[ml/(h.mm)] |

300

|

||||||